screw pump

If pump is stored for future use, it should be kept as the following requirements:

1、Stator

Strip stator from pump, and separately store it ,which is in order to avoid deformation caused by rotor’s

gravity, for the deformation will lead to difficultly start machine ,decrease capacity and pressure.The

stripped stator should be stored in a cool dry place, and avoid shine and temperature under -10 ℃.

2、Rotor

After stator is stripped down, pad rotor with wood (Pic.3-1followed). Surface of rotor except that is

made of stainless steel should be painted with antirust oil.

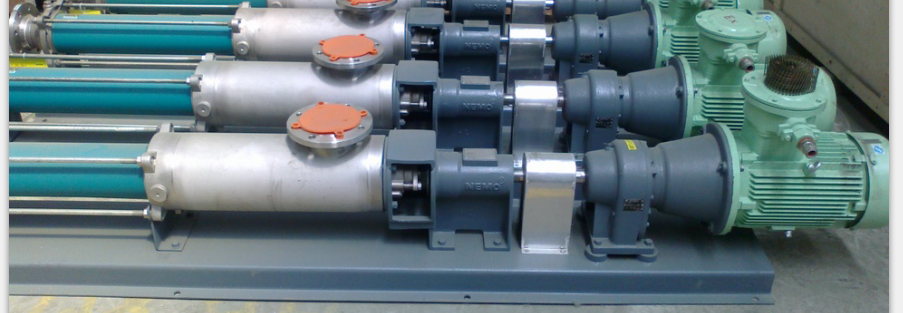

Pic. 3-1

3、Components of Packing Shaft Seal

If pump uses packing shaft seal, personnel should take the following steps:

z strip packing gland;

z dismantle packing ;

z paint surface of shaft with antirust oil.

4、 Other Components

Surface of component except that is made of stainless steel should be painted with antirust oil.

Pipeline System

All pipelines need be completely cleaned before installing pump in order to avoid welding cinder, sandy

stone and other impurities from entering pump to destroy stator.

If pump is horizontally installed, it is suggested to set up a transitional pipeline between discharge casing

and connected pipeline (Pic.4-2 followed), which is helpful to dismantle stator. The minimus length of

transitional pipeline is shown in the table 4-2

the minimum length transitional pipeline (mm)

| lead | model | ||||

| 1 | 2 | 3 | 4 | ||

| XG15 | 120 | 220 | 300 | 380 | |

| XG20 | 130 | 250 | 350 | 450 | |

| XG30 | XL002 | 200 | 300 | 400 | 500 |

| XG35 | XL005 | 250 | 400 | 550 | 700 |

| XG40 | XL008 | 300 | 500 | 600 | 700 |

Operation and Maintenance Instruction

| lead | model | ||||

| 1 | 1 | ||||

| XG50 | XL014 | 350 | 600 | 750 | 900 |

| XG60 | XL024 | 400 | 650 | 900 | 1150 |

| XG70 | XL041 | 400 | 750 | 1100 | 1450 |

| XG85 | XL069 | 500 | 900 | 1300 | 1700 |

| XG105 | XL115 | 630 | 1180 | 1740 | 2300 |

| XG135 | XL195 | 900 | 1600 | 2300 | 3000 |

| XG150 | XL330 | 1000 | 2000 | 3000 | 4000 |

| XG170 | 1200 | 2400 | 3600 | 4800 | |

| XG220 | 1500 | 3000 | 4500 |

Tel:Whatsapp

Tel:Whatsapp Tel:+86-18303261131

Tel:+86-18303261131 Email:fortunel@fdpetrol.com

Email:fortunel@fdpetrol.com Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.

Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.